OVERVIEW

CONFIGURATION

Definitions

The overall system design consists of items below.

-

CUSTOMER SITE applications. All leak points are covered

-

EMS - Emission Monitoring System detects, locates and quantifies the leak.

-

ECS - Emission Control System. EMS detects the leak and we provide customer safe handling of gas till the time of next maintenance.

-

IIOT_Service With Cloud_AI implementations, we predict the maintence requirements. Then reporting to customer for improvements, service implementations, display operations, procurement of the components.

Capabilities

EMS- Emission Monitoring System

The target is to monitor the system.

-

Points inside 100m radius can be detected

-

Up to 80 points can be checked per EMS.

-

Each EMS can communicate with others.

-

Sensor can be verified in remote.

-

Leak down to 1e-5 mbarl/s can be monitored

-

The trend graphs can be obtained to view the progress

-

The leak points can be viewed from remote.

-

The trend is calculated through Cloud AI platforms.

-

Performance of the valves and connections are monitored

-

Trigger to alarm people is sent to maintenance team.

-

The prediction of leak for components is made. The time of leak, the location of the leak, frequency of the leak are reported per connection

-

-

Predictive maintenance allows customers. ( please check calculation section for analysis

-

to prepare components in advance of planned maintenance

-

to decrease the stop time during maintenance

-

to decrease critical component stocks due to prediction of the failure

-

ECS- Emission Controlling System

The target is to control the condition of the system.

-

All points inside the EMS are valid for ECS.

-

Customers defines a leak level per connection.

-

Incase of leak, the component is ventilated. No stop is required till the planned maintenance.

-

Enables safe handling of gas due to leak. No leak allowed to environment.

Technical Background_Risks

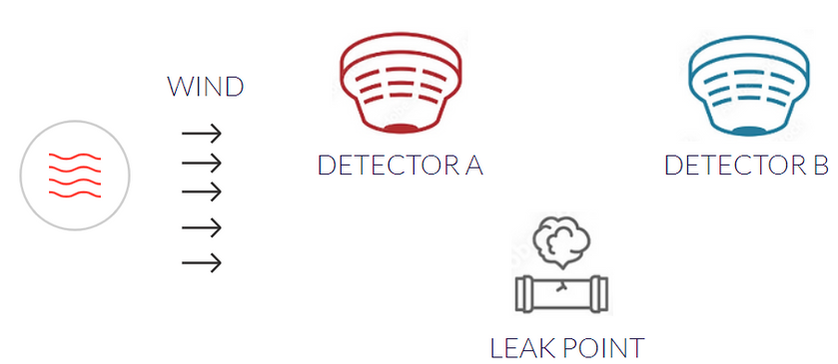

In open environment with windy weather if there is a leak as in figure above, Detector B can detect more than the value but on Detector A cannot measure anything

In USA, just at pipelines, number of explosions, the fatalities and injuries are shown as above. Just for 2018, 680 incidents are reported here but 220 more are occured in closed areas, total 900 incidents occured.

TOTAL COST of explosion in last 5 years is $ 4,568,613,427.

In closed environment, in case of leak detectors may not measure, gas can accumulate and explode.

If the sensor is alarming, you cannot define the location of the leak. Finding location is costly, and dangerous.